The Daily Shield: Your Essential Guide to FR and AR/FR Work Shirts

For workers in utilities, petrochemical, manufacturing, and electrical fields, the shirt they wear is more than just a uniform—it's a critical layer of life-saving Personal Protective Equipment (PPE). Standard work shirts can ignite, burn, and melt onto the skin, turning a minor thermal event into a catastrophic injury.

The solution is the FR (Flame-Resident) or AR/FR (Arc-Rated/Flame-Resistant) work shirt.

These garments are the first line of defense for the torso, providing crucial seconds of protection against intense heat. Selecting the right shirt means understanding the specific hazards and the strict standards that govern this essential workwear.

At Your Safety Company, we know that reliable protection starts with what you wear every day. Here is your essential guide to understanding, selecting, and caring for FR shirts.

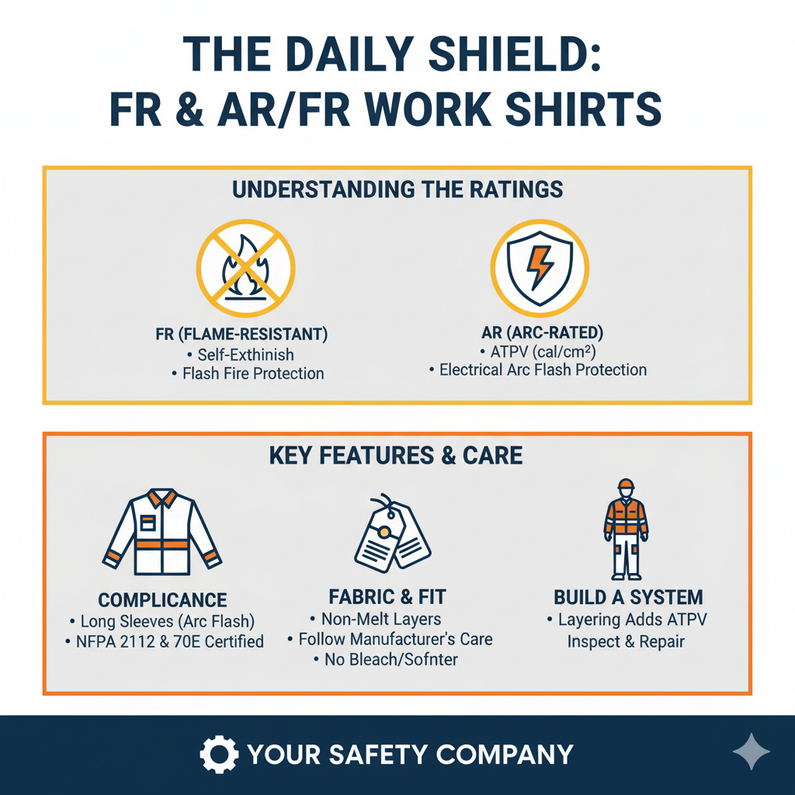

Understanding the Ratings: FR vs. AR

While the terms are often used together, they address distinct threats:

-

FR (Flame-Resistant): This is the fundamental characteristic. It means the fabric is treated or woven with materials that cause it to self-extinguish almost immediately once the source of a flame (like a flash fire) is removed. This prevents the garment itself from becoming the fuel source.

-

AR (Arc-Rated): This means the fabric has been tested against the thermal energy of an electrical arc flash. The rating is given as the ATPV (Arc Thermal Performance Value) in calories per square centimeter (cal/cm²), which measures the insulation the fabric provides.

For maximum workplace safety, most industrial companies require AR/FR Dual-Certified shirts, ensuring protection against both flash fires and electrical hazards.

The Governing Standards: NFPA 2112 and NFPA 70E

When buying an FR shirt, look for these two certification standards on the garment's tag:

-

NFPA 2112 (Standard for Flash Fire Protection): This guarantees the shirt will self-extinguish quickly, limiting the predicted body burn area to less than 50% in a 3-second flash fire exposure. This is essential for oil, gas, and chemical industries.

-

NFPA 70E (Standard for Electrical Safety in the Workplace): This standard dictates the required PPE Category (CAT)—formerly HRC—based on the calculated incident energy (cal/cm²) of a potential arc flash. Your shirt's ATPV must meet or exceed the minimum calorie rating for the required CAT level (e.g., CAT 2 typically requires a minimum of 8 cal/cm²).

Selection Nuances: Sleeves, Fabric, and Fit

Choosing the right FR shirt goes beyond the cal rating. Consider these practical factors:

Care and Maintenance: Protecting the Protection

Improper laundering is the most common reason FR shirts lose their effectiveness. To ensure the integrity of your PPE, proper care is essential, and you must follow the garment manufacturer's specific washing directions.

-

Follow Manufacturer's Directions: Always check the tag for the manufacturer's instructions regarding temperature, cycle, and detergent. Failure to follow these directions can void the garment's FR integrity.

-

Avoid Bleach and Fabric Softeners: Chlorine bleach and common fabric softeners can break down the flame-resistant treatment or leave residues that compromise the garment's protective capabilities.

-

Wash Separately: Wash FR garments separately from non-FR laundry to prevent transfer of combustible materials like cooking grease or automotive fluids.

-

Check Condition: Regularly inspect shirts for tears, holes, or heavily contaminated areas. If the integrity of the fabric is compromised, the garment must be immediately removed from service and repaired with FR thread and FR patches, or retired.

Your Safety Company: Equipped for Every Hazard

The AR/FR shirt is the daily shield for industrial workers. It is the crucial piece of gear that buys valuable seconds during an incident, preventing life-altering injuries. By selecting garments certified to NFPA 2112 and with the correct NFPA 70E rating, you are investing directly in the health and operational continuity of your business.

At Your Safety Company, we offer a comprehensive selection of certified AR/FR shirts, coveralls, and outerwear, ensuring your team has the right protection for their specific thermal hazard.

Don't compromise your daily defense. Visit yoursafetycompany.com today to explore our full line of compliant, comfortable FR work shirts.

Recent Posts

-

The Eyewash Station: Your First Line of Defense in an Eye Emergency

In any workplace, safety should always be a top priority. When it comes to eye safety, every second …2nd Mar 2026 -

The Unsung Hero of Consistency: Why Your Team Trusts the Same Safety Supplies

Imagine trying to bake a cake with a different brand of flour, sugar, and eggs every time. The resul …27th Feb 2026 -

The Hidden Cost of "The Walk": Why Accessible Safety Supplies Matter

In a busy facility, time isn’t just money—it’s momentum. One of the most common "hidden costs" in pr …26th Feb 2026