The Clear Difference: Your Essential Guide to Eye and Face Protection

A clear line of sight is vital for performing any job safely and effectively. Yet, every day, thousands of workers suffer preventable eye injuries—injuries that can result in temporary vision loss, blindness, and career-ending trauma. The vast majority of these incidents occur simply because the worker was either not wearing appropriate eye protection or was wearing the wrong type of protection for the hazard.

Effective eye and face protection is about far more than just wearing a pair of clear safety glasses. It requires a meticulous assessment of the workplace environment to match the specific hazard to the correct type of protective equipment.

At Your Safety Company, we believe safety must be 20/20. Let's look closely at the primary hazards and the essential features of protective eyewear.

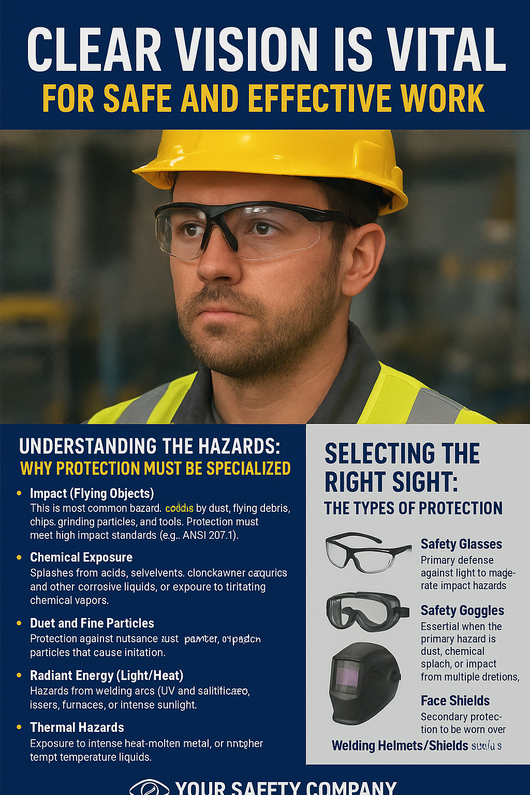

Understanding the Hazards: Why Protection Must Be Specialized

Workplace eye injuries stem from a variety of sources. A single piece of eyewear cannot protect against them all:

-

Impact (Flying Objects): This is the most common hazard, caused by dust, flying debris, chips, grinding particles, and tools. Protection must meet high impact standards (e.g., ANSI Z87.1).

-

Chemical Exposure: Splashes from acids, solvents, caustics, and other corrosive liquids, or exposure to irritating chemical vapors. This requires a full, sealed barrier.

-

Dust and Fine Particles: Protection against nuisance dust, powder, and windblown particles that cause irritation and distraction.

-

Radiant Energy (Light/Heat): Hazards from welding arcs (UV and infrared), lasers, furnaces, or intense sunlight. Requires specialized filtering lenses.

-

Thermal Hazards: Exposure to intense heat, molten metal, or high-temperature liquids.

Selecting the Right Sight: The Types of Protection

Your hazard assessment should lead directly to selecting one of these primary types of protection:

-

Safety Glasses:

-

Purpose: Primary defense against light to moderate impact hazards.

-

Key Features: Must have strong polycarbonate lenses and integral or attached side shields to protect against peripheral hazards. They must be marked with the appropriate high-impact rating.

-

Specialty: Often feature anti-fog coatings for humid environments and various tints or UV filters for outdoor work.

-

-

Safety Goggles:

-

Purpose: Essential when the primary hazard is dust, chemical splash, or impact from multiple directions.

-

Key Features: Form a tight seal around the eyes, offering 360-degree protection.

-

Indirectly Vented: Best for chemical splash or dust environments, as vents prevent fogging but block liquid entry.

-

Directly Vented: Suitable for dust and impact where splash is not a risk.

-

-

-

Face Shields:

-

Purpose: Secondary protection to be worn over safety glasses or goggles. They protect the entire face from large splashes, flying debris, or moderate heat.

-

Key Features: Must extend from the forehead down to below the chin and across the width of the face. Never wear a face shield without primary eye protection underneath.

-

-

Welding Helmets/Shields:

-

Purpose: Specialized protection against extreme radiant energy (UV/IR) and intense heat from welding arcs.

-

Key Features: Feature auto-darkening lenses that quickly switch protection levels and filter out harmful light. They are often worn over safety glasses.

-

Tips for Compliance and Comfort

Even the best eyewear is useless if it's sitting on a workbench. Ensure employee compliance by prioritizing comfort and maintenance:

-

Fit is Critical: Eyewear should fit snugly without pinching or slipping. Ensure the size is correct for the individual.

-

Cleanliness: Provide accessible cleaning stations and anti-fog wipes. Dirty or scratched lenses impair vision, encouraging workers to remove them.

-

Prescription Needs: Workers who require corrective lenses must be provided with safety glasses that fit over their glasses, or prescription safety eyewear that meets the required impact standards.

-

Regular Inspection: Eyewear should be routinely inspected for deep scratches, cracks, bent frames, or missing side shields, and replaced immediately if protection is compromised.

Your Safety Company: Clear Vision for Workplace Safety

Protecting your team's vision is one of the most effective and least costly ways to prevent permanent, debilitating injuries. By conducting a detailed hazard assessment and selecting the correct protective eyewear, you are investing directly in the long-term health and productivity of your workforce.

At Your Safety Company, we provide an extensive inventory of safety glasses, chemical goggles, face shields, and specialty eyewear designed to meet or exceed the highest impact standards.

Don't let a moment of compromise cost a lifetime of sight. Visit yoursafetycompany.com today to explore our comprehensive line of eye and face protection.

Ready to ensure your team has the perfect vision protection? Contact us for expert advice on selecting the right specialty eyewear for your hazards!

Recent Posts

-

The Eyewash Station: Your First Line of Defense in an Eye Emergency

In any workplace, safety should always be a top priority. When it comes to eye safety, every second …2nd Mar 2026 -

The Unsung Hero of Consistency: Why Your Team Trusts the Same Safety Supplies

Imagine trying to bake a cake with a different brand of flour, sugar, and eggs every time. The resul …27th Feb 2026 -

The Hidden Cost of "The Walk": Why Accessible Safety Supplies Matter

In a busy facility, time isn’t just money—it’s momentum. One of the most common "hidden costs" in pr …26th Feb 2026