Beyond the Spark: An Essential Guide to Workplace Electrical Safety

Electricity powers our modern world, enabling everything from office computers to heavy industrial machinery. Its ubiquity, however, often leads to complacency regarding its inherent dangers. While we rely on it constantly, electricity remains one of the most serious and common hazards in any workplace.

At Your Safety Company, we know that effective electrical safety goes far beyond simply avoiding a spark. It requires vigilance, proper procedures, and the right protective gear. Let's illuminate the critical aspects of workplace electrical safety to keep your employees safe and your operations running smoothly.

Understanding the Silent Threat: Common Electrical Hazards

Electrical accidents can lead to severe injuries, including electric shock, burns, falls (due to shock), and even death. They can also cause fires and explosions. Here are some of the most common electrical hazards found in workplaces:

-

Exposed Electrical Parts:

-

Damaged insulation on wires, open electrical panels, or uncovered junction boxes expose live components, creating a direct path for electric current.

-

-

Inadequate Wiring:

-

Using undersized wires for the current they carry, worn-out wiring, or improper grounding can lead to overheating, short circuits, and fire.

-

-

Overloaded Circuits:

-

Plugging too many devices into a single outlet or circuit can draw excessive current, causing wires to overheat and potentially ignite.

-

-

Damaged Power Tools & Cords:

-

Frayed cords, broken plugs, or tools with damaged insulation are a common source of electrical shocks and fires.

-

-

Lack of Lockout/Tagout (LOTO) Procedures:

-

Failure to properly de-energize and lock out electrical equipment during maintenance or repair exposes workers to unexpected energization.

-

-

Wet Conditions:

-

Water is a conductor of electricity. Working with or around electrical equipment in damp or wet environments dramatically increases the risk of shock.

-

Essential Pillars of Workplace Electrical Safety

Mitigating electrical hazards requires a multi-faceted approach.

-

Regular Inspections & Maintenance:

-

Periodically inspect all electrical equipment, cords, outlets, and panels for signs of wear, damage, or overheating. Promptly repair or replace faulty items.

-

Ensure all electrical installations comply with relevant codes (e.g., NFPA 70E, OSHA).

-

-

Proper Grounding & GFCI Protection:

-

Grounding provides a safe path for electricity to dissipate in case of a fault.

-

Ground Fault Circuit Interrupters (GFCIs) detect imbalances in current flow and quickly shut off power, offering crucial protection in damp or outdoor environments.

-

-

Safe Work Practices:

-

De-energize First: Whenever possible, de-energize circuits and equipment before working on them.

-

Maintain Clearance: Keep work areas around electrical equipment clear.

-

Avoid Overloading: Never overload circuits.

-

Use Tools Safely: Operate power tools according to manufacturer instructions and inspect them before each use.

-

-

Lockout/Tagout (LOTO) Procedures:

-

Crucial for maintenance and repair: LOTO ensures that dangerous machines or equipment cannot be re-energized unexpectedly during servicing. This involves physically locking the power source in the "off" position and attaching a tag.

-

Action for Businesses: Develop, implement, and rigorously enforce a comprehensive LOTO program, including regular employee training.

-

-

Employee Training:

-

All employees should be trained on basic electrical safety awareness.

-

Those who work directly with or around electrical systems need specialized training on hazard recognition, safe work practices, LOTO procedures, and emergency response.

-

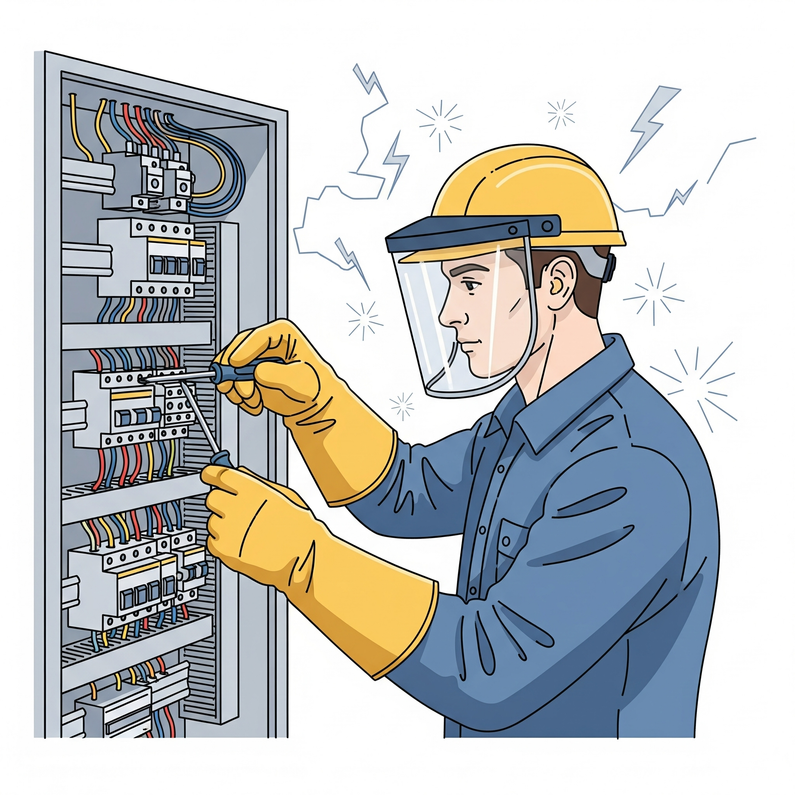

The Right Gear: Your PPE for Electrical Protection

Personal Protective Equipment (PPE) is a critical component of electrical safety, especially for qualified workers performing tasks on or near energized equipment. Your Safety Company provides essential products for electrical protection:

-

Insulated Gloves: Specifically designed to protect against electric shock, these gloves come in various classes depending on the voltage.

-

Non-Conductive Footwear: Safety boots with electrical hazard (EH) ratings provide a secondary layer of protection against open circuits.

-

Face Shields & Arc Flash Shields: Essential for protecting the face and eyes from the intense heat and light of an arc flash incident.

-

Flame-Resistant (FR) Clothing: Protects against the thermal hazards of an arc flash.

-

Lockout/Tagout Devices: A full range of padlocks, hasps, cable lockouts, and tags to securely de-energize equipment.

-

Voltage Detectors & Testers: Non-contact testers are vital for verifying that circuits are de-energized before work begins.

Remember: PPE is the last line of defense. It must always be used in conjunction with safe work practices, engineering controls, and administrative controls.

Power Up Your Safety Program with Your Safety Company

Ignoring electrical safety is a gamble no business can afford. Investing in proper training, adherence to safety procedures, and the right protective equipment safeguards your employees, prevents costly downtime, and protects your reputation.

Recent Posts

-

The Eyewash Station: Your First Line of Defense in an Eye Emergency

In any workplace, safety should always be a top priority. When it comes to eye safety, every second …2nd Mar 2026 -

The Unsung Hero of Consistency: Why Your Team Trusts the Same Safety Supplies

Imagine trying to bake a cake with a different brand of flour, sugar, and eggs every time. The resul …27th Feb 2026 -

The Hidden Cost of "The Walk": Why Accessible Safety Supplies Matter

In a busy facility, time isn’t just money—it’s momentum. One of the most common "hidden costs" in pr …26th Feb 2026