Beyond "One Size Fits All": Matching Glove Mil-Thickness to Your Specific Task

In many facilities, the "standard blue nitrile glove" is treated like a commodity—ordered in bulk and used for everything from light dusting to handling harsh chemicals. But if you’re using the same glove for every department, you’re likely either overspending on protection you don’t need or under-protecting your team where it matters most.

Today, we’re breaking down the "Mil-Thickness Map" to help you choose the right barrier for your specific work environment.

The 3 Mil Standard: Precision & Tactile Sensitivity

-

The Task: Dental exams, lab work, electronics assembly, and fine motor tasks.

-

The Choice: ProWorks® GL-N103EPF.

-

Why it works: When your job depends on "feel," every millimeter counts. A 3 mil glove acts as a second skin, reducing hand fatigue and allowing for high-precision movement. If your team complains about "bulky" gloves, this is your solution.

The 4 Mil Workhorse: Versatility Across Environments

-

The Task: Food service, general clinical use, light janitorial, and high-volume processing.

-

The Choice: ProWorks® GL-N135F.

-

Why it works: This is the "Goldilocks" of gloves. It’s tough enough to handle a full shift in a kitchen or a clinic without tearing, but light enough to stay comfortable. It’s the ideal choice for facilities that need one reliable glove that can jump between different departments.

The 5.5 Mil Barrier: Durability for High-Risk Tasks

-

The Task: Automotive repair, chemical handling, and heavy-duty maintenance.

-

The Choice: ProWorks® GL-N106F.

-

Why it works: When the environment gets aggressive, you need a barrier that won't quit. At 5.5 mil, you’re gaining significant puncture resistance. This is the glove for the "hands-on" worker who deals with tools, snags, and environmental stressors that would shred a standard exam glove.

Are You Using the Right Tool?

Choosing the wrong glove isn't just a safety issue—it's a budget issue. Using a heavy-duty 5.5 mil glove for a task that only requires a 3 mil "second-skin" fit is essentially throwing money away. Conversely, using a thin glove for a heavy-duty task leads to "double-gloving" and wasted product.

Stop guessing and start optimizing. We specialize in helping facilities audit their current glove usage to ensure every department has exactly what they need—no more, no less.

Recent Posts

-

The "Set it and Forget it" Fallacy: Weekend Safety Prep

As the weekend approaches and shifts change, facility managers are often busy checking locks and pow …6th Mar 2026 -

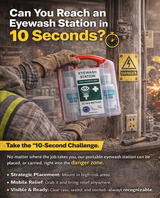

The "10-Second Rule": Is Your Eye Relief Close Enough?

In the world of emergency response, there is a golden rule: The 10-Second Rule. If a worker is expos …5th Mar 2026 -

Why Tap Water Isn't Enough: The Science of Professional Eye Relief

In an emergency, the instinct is to grab the nearest liquid to flush an eye. While any water is bett …4th Mar 2026